|

| Beyer M320. Do not stick it in your kick drum! |

The M320 makes good use of plastic for the body, and has all the style of a brick! A Beyer catalogue* from 1965 called it a "heavy-duty dynamic type for show business use", and the switch allows the use to select 'music' or 'speech' settings, the latter giving a bass attenuation of 12dB at 50Hz. Because of its appearance and a vague resemblance to the AKG D12, it is tempting to thing that this is designed for inside a bass drum. It is not.

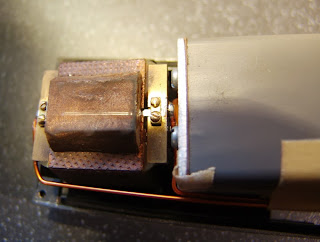

The M320 has the same motor that is found in the M260, but is connected to a large rectangular chamber below the mic via a tube. I have not been brave / stupid enough to cut open the chamber to see what is going on inside, but one assumes a series of interconnected tubes forming an acoustic labyrinth.

|

| Beyer M320 inside |

Although the M320 is called 'heavy duty', the M360 is much more sturdy, with a metal housing and grill. The catalog calls it a "dynamic unidirectional studio microphone with ultra-modern styling". Again, it is as elegant as a 1980s Volvo, but at least form follows function in these mics!

|

| Beyer M360. Ultra-modern? |

|

| ... or just ugly? |

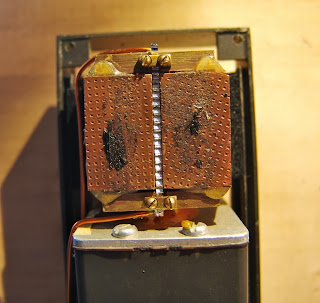

The M360 is slightly larger and like the M320 it also has an acoustic chamber below the ribbon motor. I was fully expecting to see the same motor in this mic as is found in the other Beyerdynamic ribbon microphones of the same era, so was suprised to find something quite different. Rather than being assembled from four small magnets glued together, the M260 has a larger cast magnet with two copper coloured pole pieces which may also be a magnetic alloy.

|

| Beyer M360 motor |

Although the motor is wider and deeper, it still accommodates the same size of ribbon. And the magnetic field measures around 5000 Gauss, which is similar to a 'normal' healthy Beyerdynamic motor. So I am really not sure why this uses a different motor. Perhaps it was an early production run. The transformer and switch (on/off) are housed below the acoustic chamber below the microphone.

In the photo above, the ribbon is fully corrugated, but another specimen (below) had a standard Beyer ribbon, which seems more likely to be the original.

Both mics sound good when working properly, with a cardioid pickup, a relatively flat response and a bit less proximity effect than you would find in a figure-8 ribbon. They use the typical tiny Beyer transformers, which in the case of the M60 at least is wound for a full range response.

*Here is the full Beyerdynamic catalog from 1965, at the excellent Coutant website.